A mechatronics student

Musa Kırkan

3D CAD & PCB Designer | Embedded Systems Learner | Mechatronics

Work Experience

Industrial Agricultural Solar PV Systems

I worked at Konyasolar on grid-connected (on-grid) agricultural irrigation projects. These projects provided power for large submersible pumps that pump water from wells up to 400 meters deep and need up to 180 Amperes of current.I helped install systems with up to 256 solar panels and supported the safe connection of high-power electrical lines.

Completed Projects

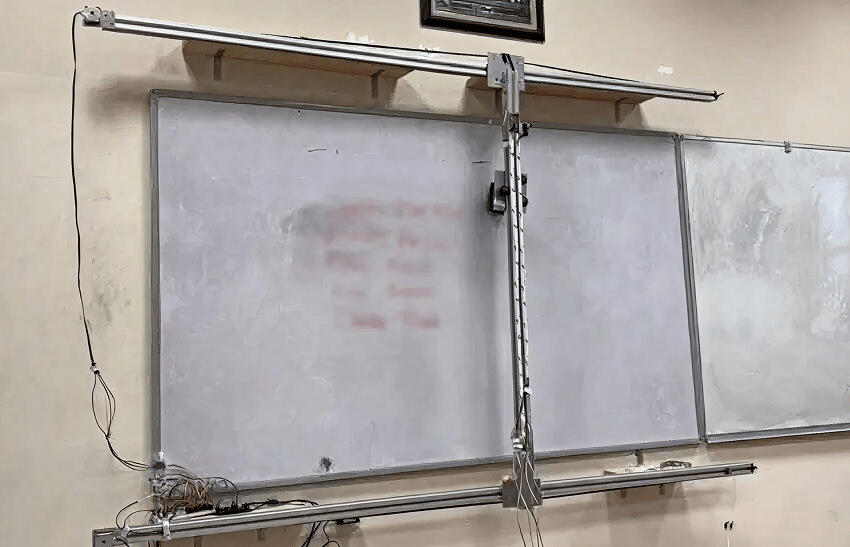

Automatic Whiteboard Cleaning System

This system is designed to increase efficiency in high-usage areas such as schools and offices by automating the cleaning of whiteboards. It was developed using a GT2 belt mechanism and three Nema 17 stepper motors (two for the X-axis and one for the Y-axis) to achieve precise linear motion along the X and Y axes.The cleaning head features an eraser mechanism powered by a 6V high-torque DC motor that rotates around its own axis to effectively remove ink from the surface. The project’s control unit is based on an Arduino, and the system is triggered via a physical button. For future development, integration with a mobile application using ESP32 and remote control capabilities are planned.

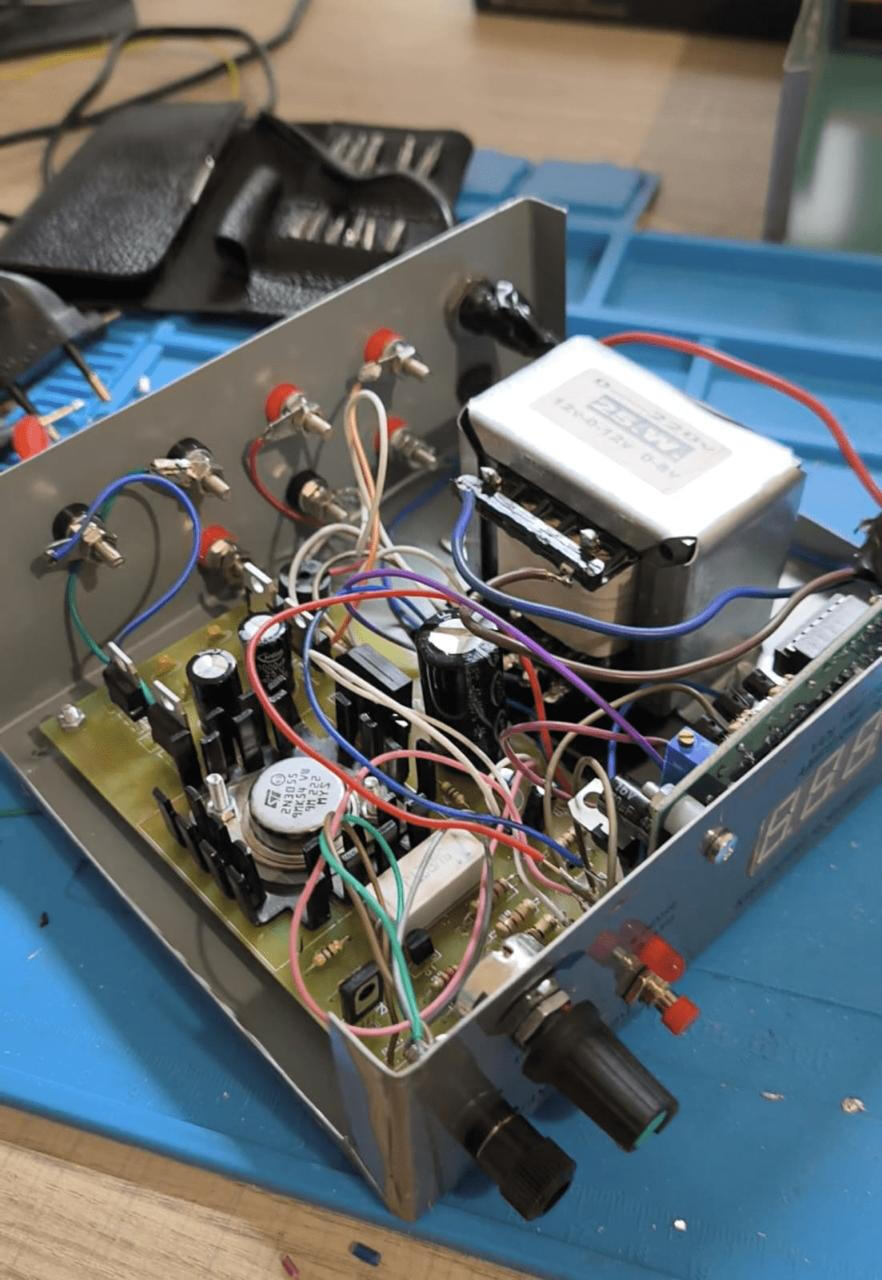

Adjustable AC–DC Power Supply

This project is a custom-built power supply unit where I executed every stage, from soldering individual PCB components to the final mechanical chassis assembly. Powered by a 25W transformer, the system is designed to meet diverse laboratory needs.It features fixed symmetric DC outputs (+12V/-12V, +5V/-5V), a 12V AC output, and a fully adjustable 0-24V DC channel. A built-in digital display allows for real-time monitoring of voltage and current levels. Currently fully functional, this unit serves as the primary power source for testing and prototyping my ongoing electronics projects.

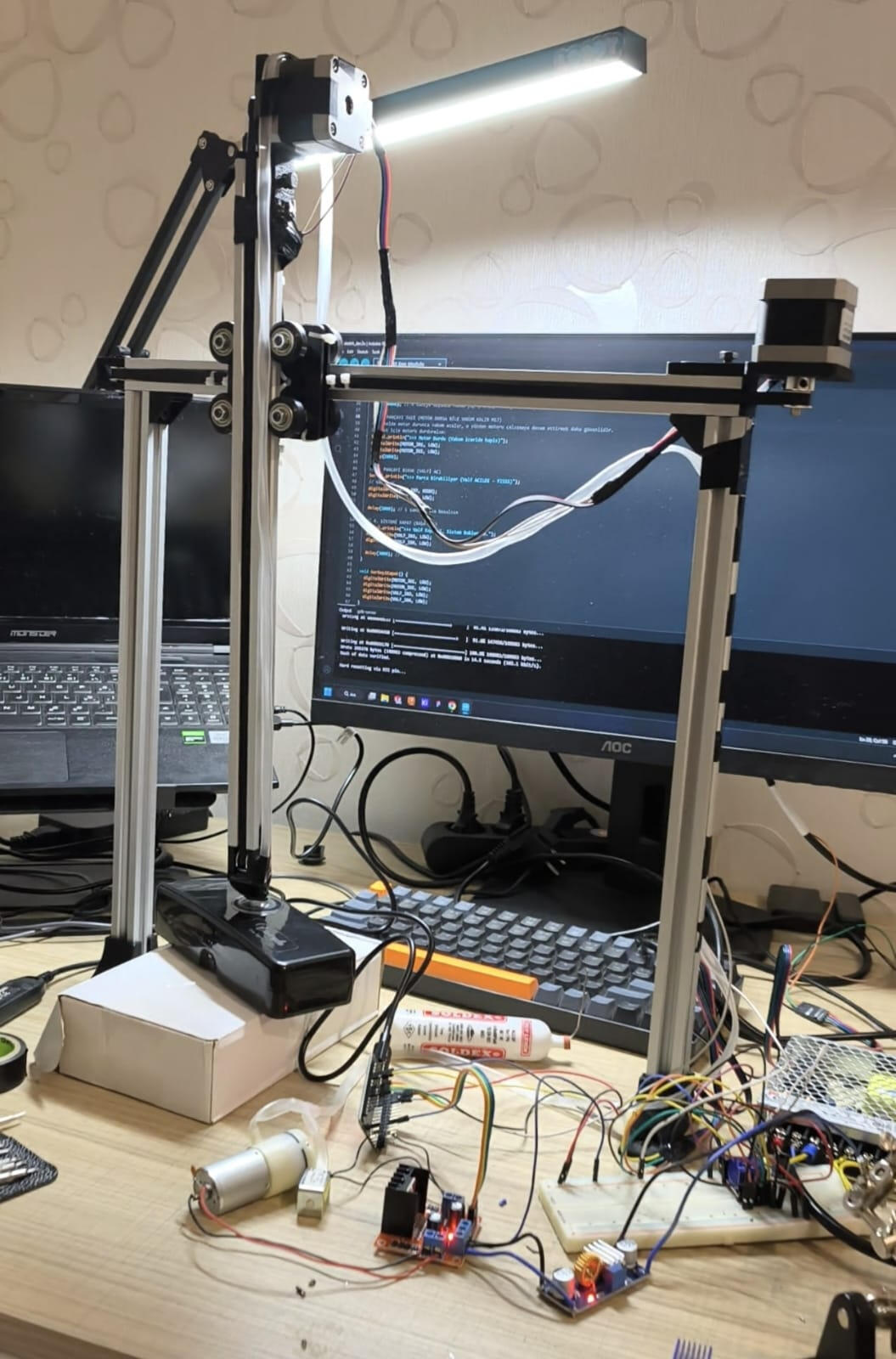

Pick & Place System

In this project, which models automation systems used in industrial production lines, a 2-axis (X-Z) Pick and Place robot was designed and built. The mechanical structure was developed using linear rails and sliders, belt-pulley mechanisms, stepper motors, and flexible silicone cables to ensure high precision.The control unit is based on an ESP32 microcontroller, adding Industry 4.0 capabilities to the system. Thanks to Wi-Fi connectivity, the robot can be wirelessly controlled via a custom mobile application, its real-time status can be monitored, and the integrated camera module allows visual tracking of the operation process.The project’s main strength is its modular design: the system can handle electronic components with a vacuum gripper, and by changing the end effector, it can work with larger parts using mechanical claws. This makes it a flexible engineering prototype that can be quickly adapted to different production scenarios such as PCB assembly and packaging.

Ongoing Projects

Cartesian Plotter

A Cartesian plotter is a two-axis (X–Y) motion system that converts digital vector data into precise linear movements, enabling accurate drawing, plotting, or marking on a flat surface using a pen or similar tool. The system typically interprets G-code commands to control stepper motors and produce repeatable, high-precision technical drawings.